Precision Engineering Solutions

Innovating the future of manufacturing

Welcome to Top Tech Industries

Precision Machined Components & Engineering Solutions Since 1996

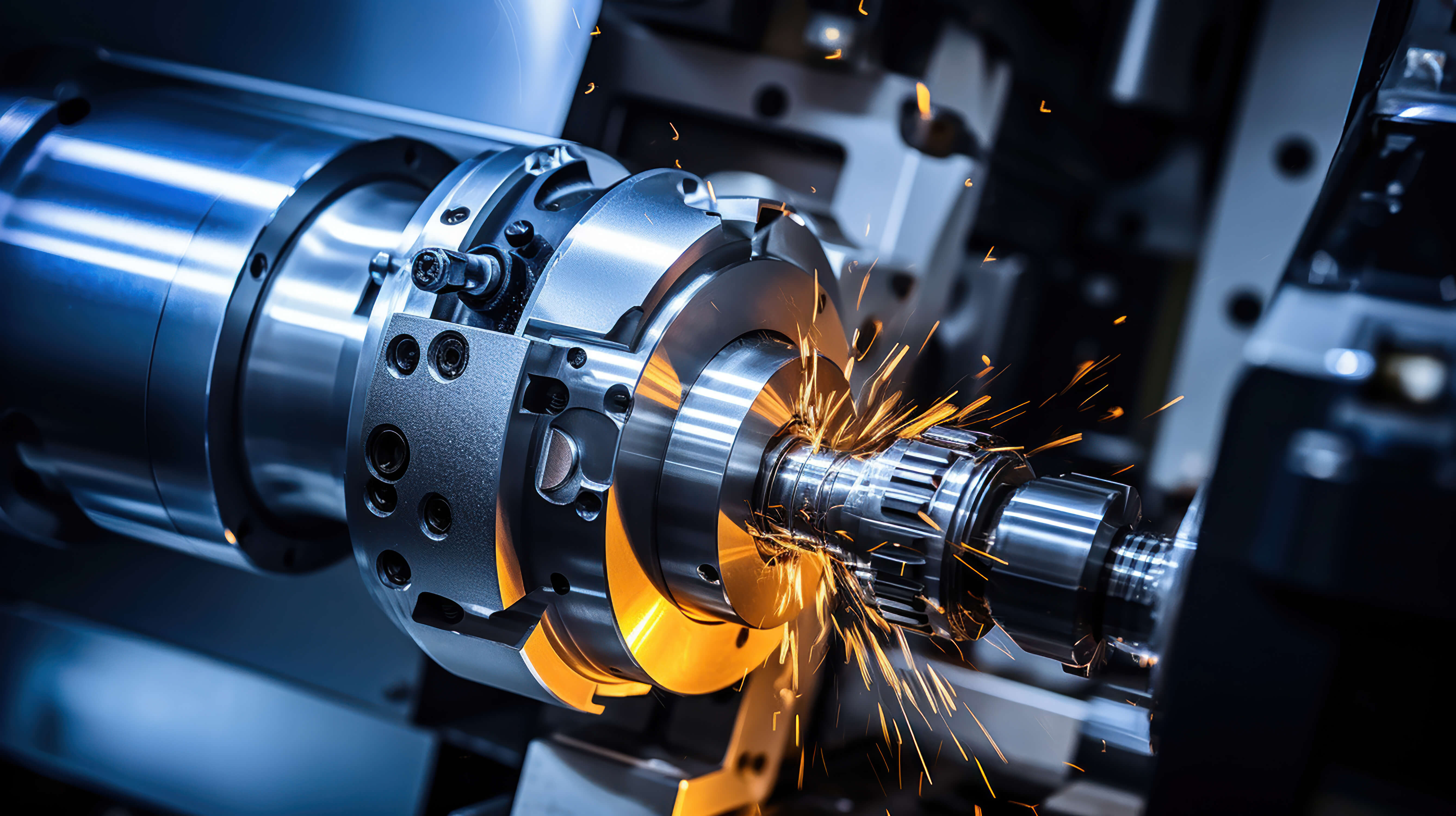

"With over 30 years of expertise, Top Tech Industries is a leading manufacturer of precision machined components, serving diverse industries across domestic and international markets. Established in 1996, we specialize in CNC machining, multi-axis milling, turning, and custom-engineered parts with a focus on quality, durability, and customer satisfaction. Equipped with advanced technologies and a skilled workforce, we deliver precise solutions for industries such as oil and gas, energy, hydraulics. Through innovation and continuous improvement, we ensure on-time delivery and robust quality control, earning the trust of clients worldwide."